Whisker Countermeasures

However, in some cases, needle-like crystals called whiskers grow after plating, causing short circuits and damage to electronic circuits.

This tendency is particularly noticeable in areas subject to external pressure, such as the joint areas.

Mechanism of whiskey production

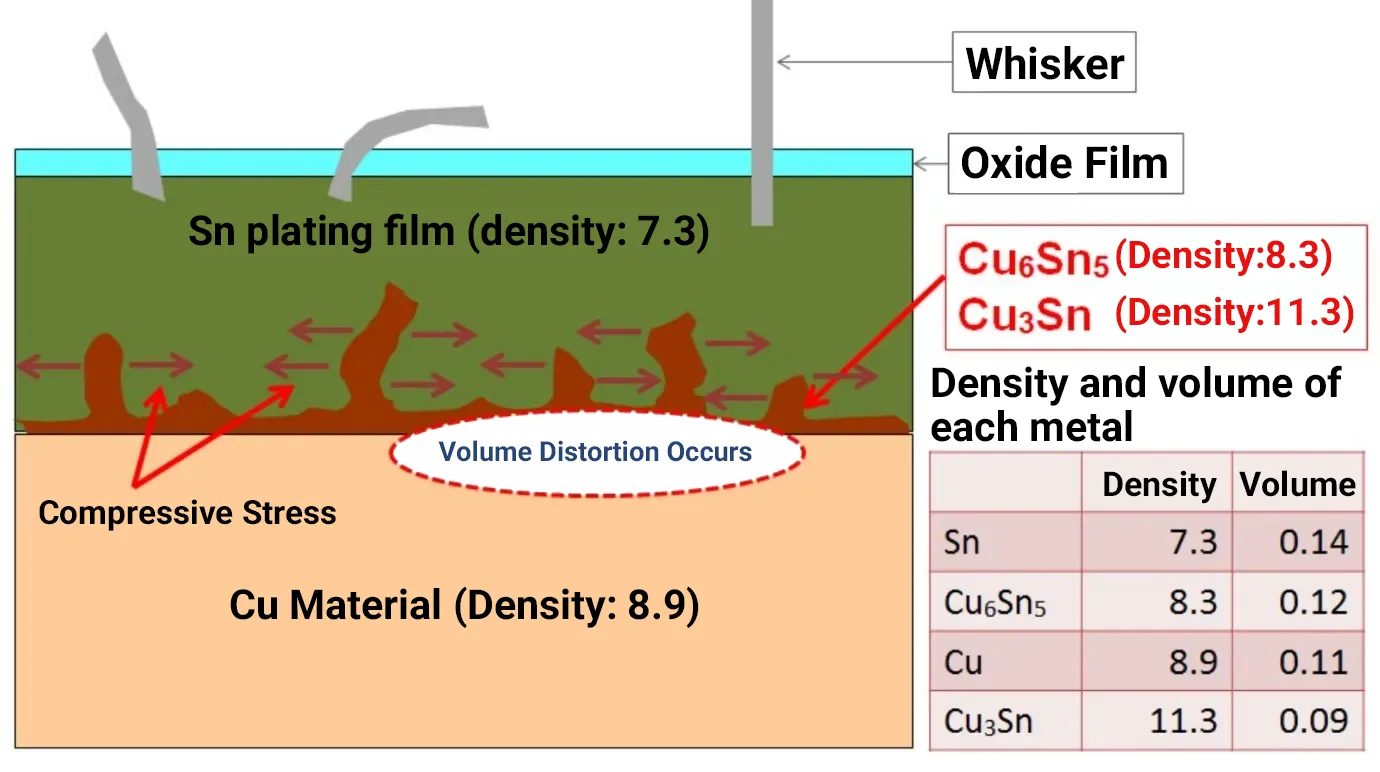

An alloy layer is formed between the Cu base and Sn due to mutual diffusion.

The diffusion alloy layer mainly formed by leaving the material at room temperature is “Cu6Sn5,” which has a volume larger than Cu and smaller than Sn.

The compressive stress caused by this volume change (expansion) drives the growth of whiskers.

In addition, stress applied directly from outside generates whiskers in a shorter period of time.

This cannot be prevented even with various Sn alloys.

Wiskas countermeasures

Our company solves these problems with various measures tailored to usage and cost.

In all cases, there have been no instances of whisker formation for over 10 years, demonstrating long-term quality stability.

Wiskas countermeasures

①A Ni plating is applied as a diffusion barrier layer.

②Perform reflow after Sn plating.

③Perform annealing after Sn plating.

④Perform Sn alloy plating.

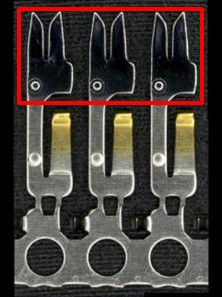

Partial Sn reflow plating

Our company has introduced a partial tin plating process and an online reflow process to the hoop line, enabling partial tin reflow plating in a single process.

Our company solves these problems with various measures tailored to usage and cost.

In both cases, there have been no instances of whisker formation for over 20 years, demonstrating long-term quality stability.