Partial Plating

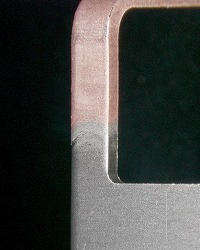

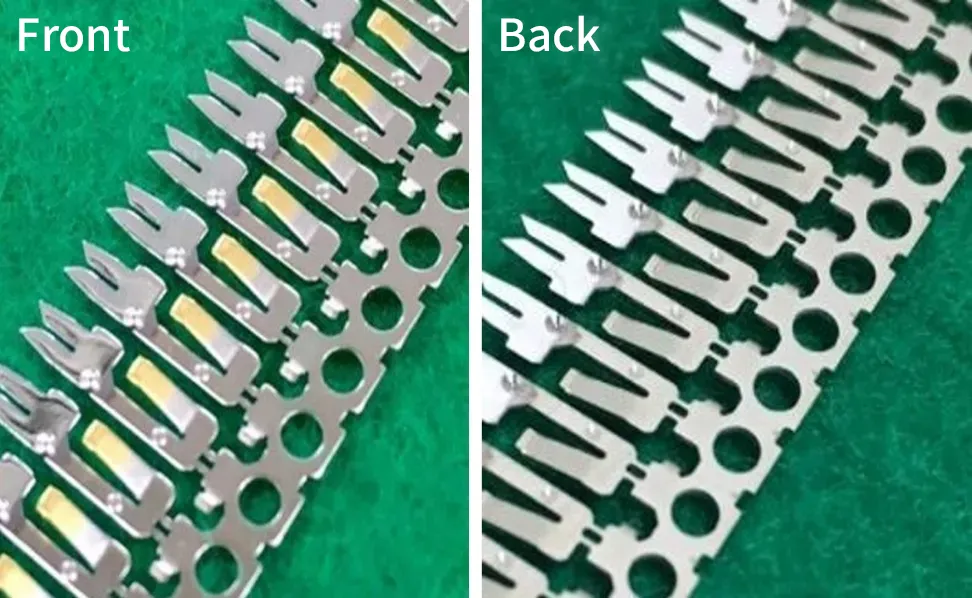

Liquid surface method Partial Ni plating

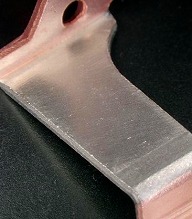

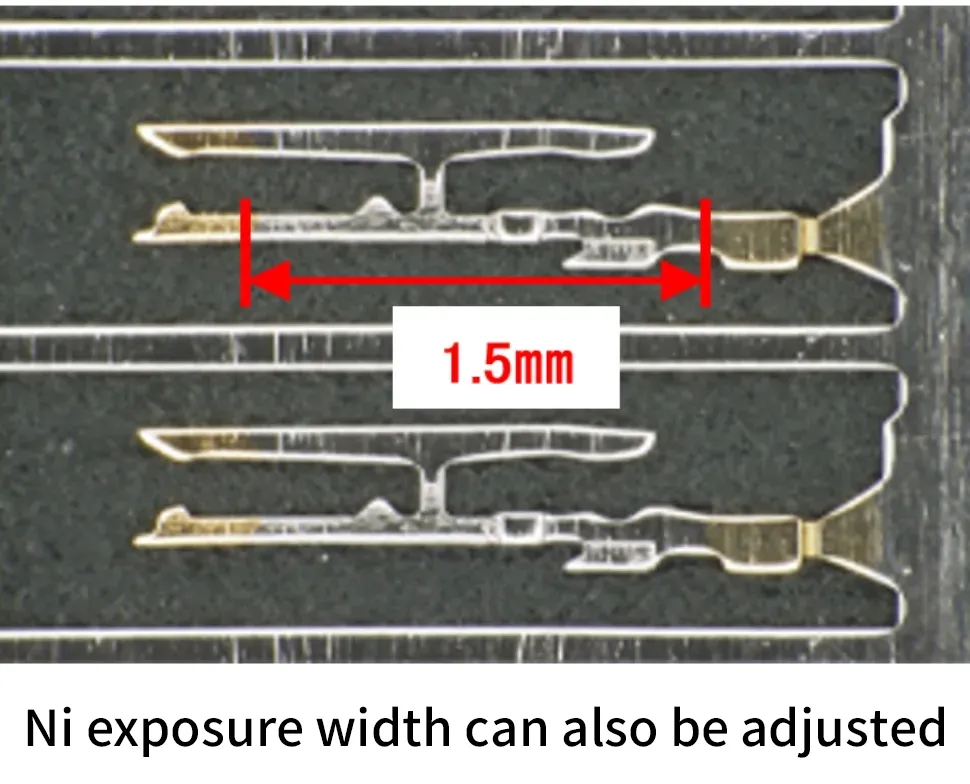

Masking method Partial Ni plating

Recently, there has been an increase in demand for partial plating of power module electrode parts and other components.

Our company is also working on partial plating in order to meet customer requests.

Partial plating can cause problems in subsequent processes because plating is applied to specific areas.

For example, switching from solder joints to metal-to-metal joints.

(Concerns about cracks in solder due to long-term vibration, electrical resistance remains unchanged with the same metal)

Things started to take off around 2010, and as of 2025, we are receiving many inquiries.

Our company proposes partial plating tailored to the product using methods such as liquid surface and masking.

Masking method Partial Ni plating

Masking method Partial Ni platingt=0.8mm

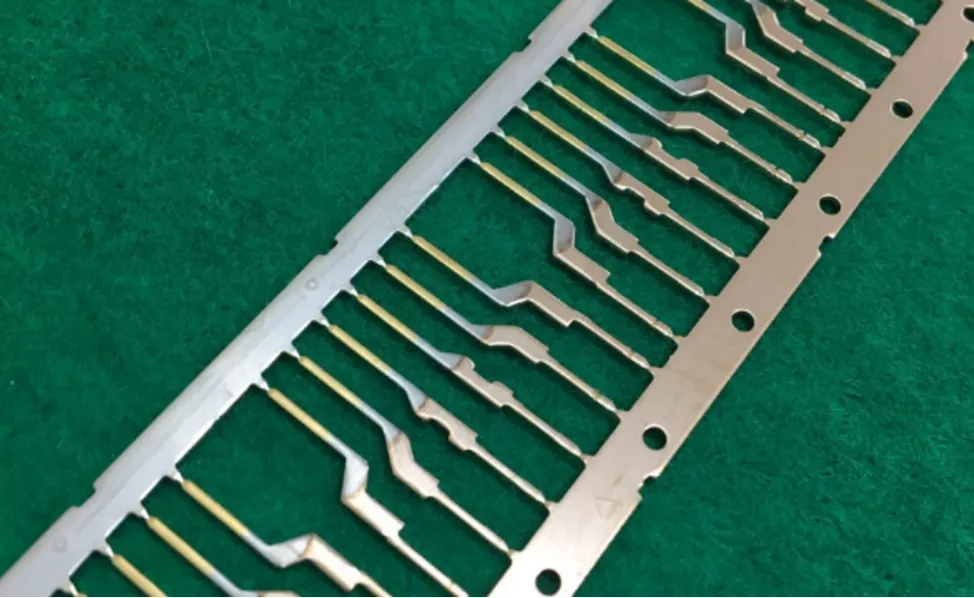

Masking method Partial Sn plating

Masking method Partial Sn platingt=0.8mm

Partial Au plating method

Cost reduction can be achieved through gold plating of the Ueda plating section, which eliminates the need for gold plating and peeling processes.

Method-1 : Liquid level method

- Resolved Issues

- Partial Au plating with reduced equipment costs

- Countermeasure Technology

- Partial plating by immersion depth

- Merits

- Cost Reduction/Minimal thickness difference in the carrier section is also possible.

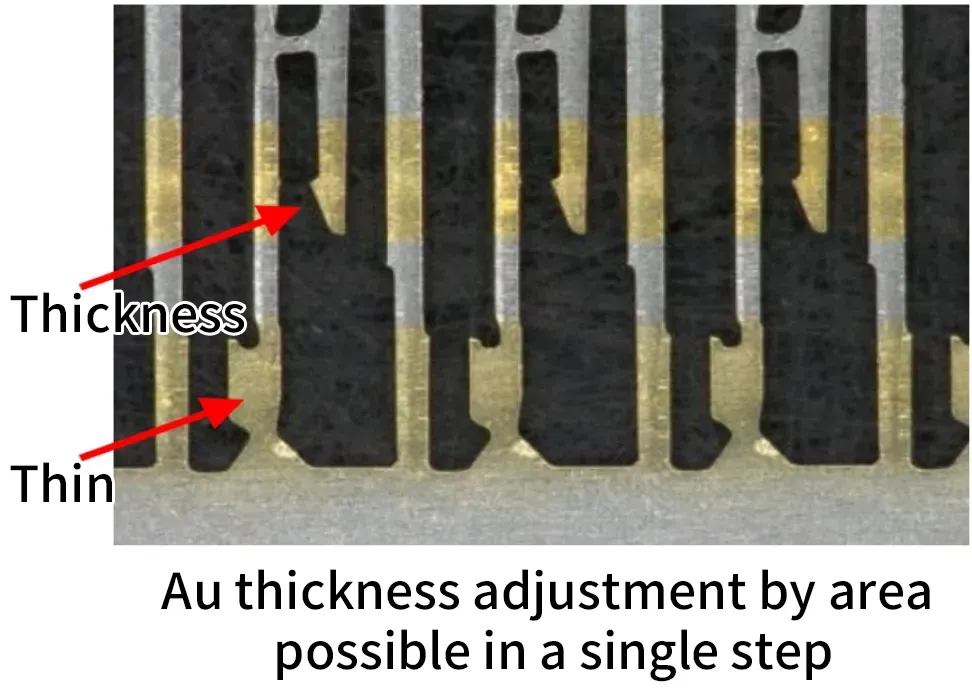

Method-2 : Sparger Method

- Resolved Issues

- Partial thickness, no plating on reverse side

- Countermeasure Technology

- Partial plating using intermittent feed + sputter mask

- Merits

- Cost reduction through more flexible Au control

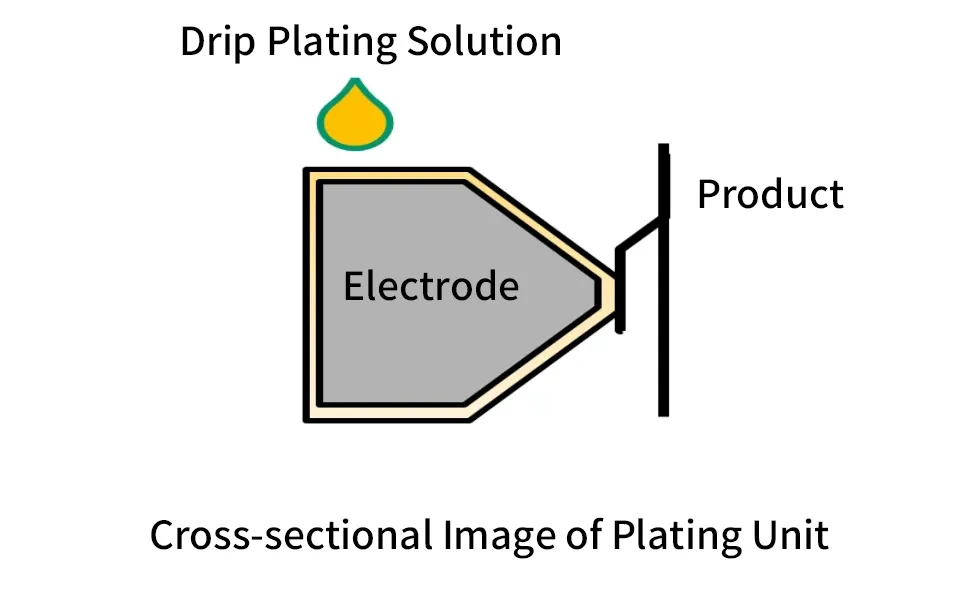

Method-3 : Original single-sided cell method

- Resolved Issues

- Single-sided stripe Au plating

- Countermeasure Technology

- Development of contact plating unit

- Merits

- Cost reduction achieved through continuous conveyor strip plating

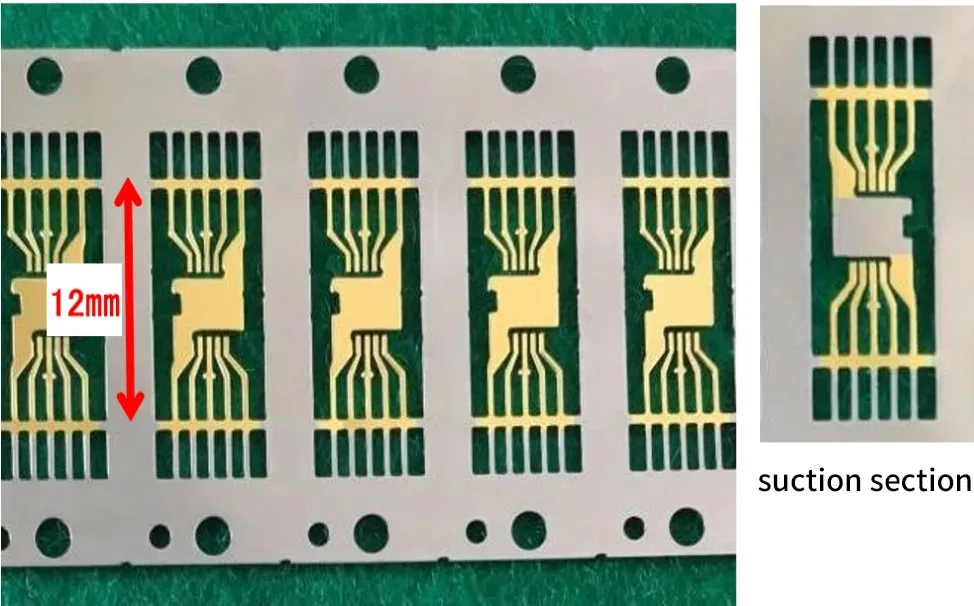

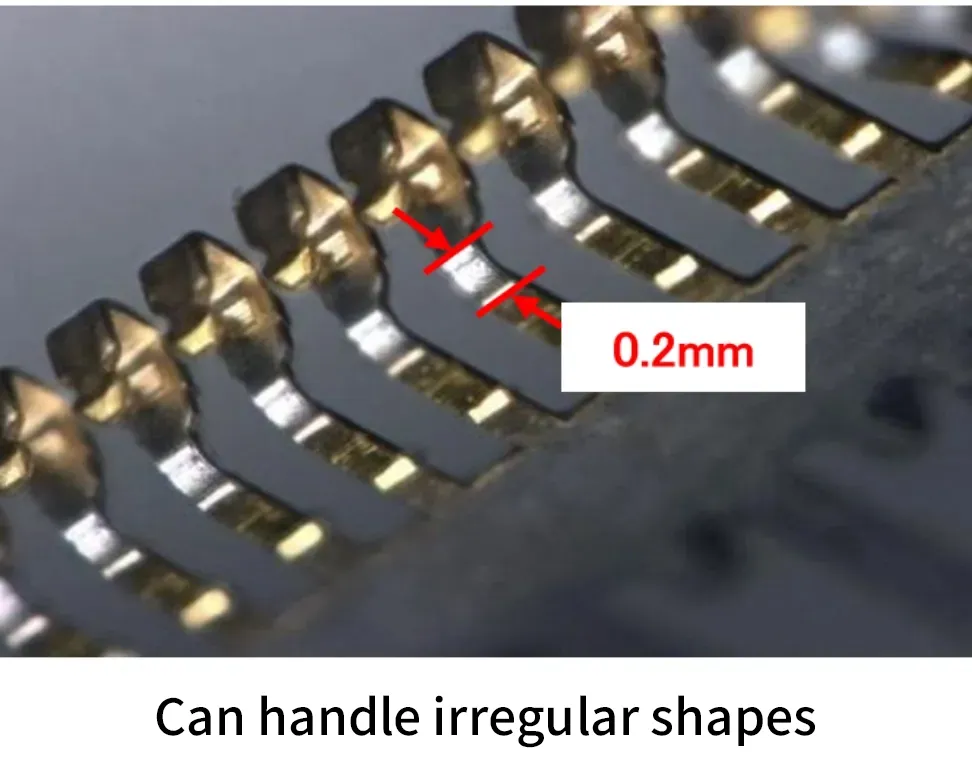

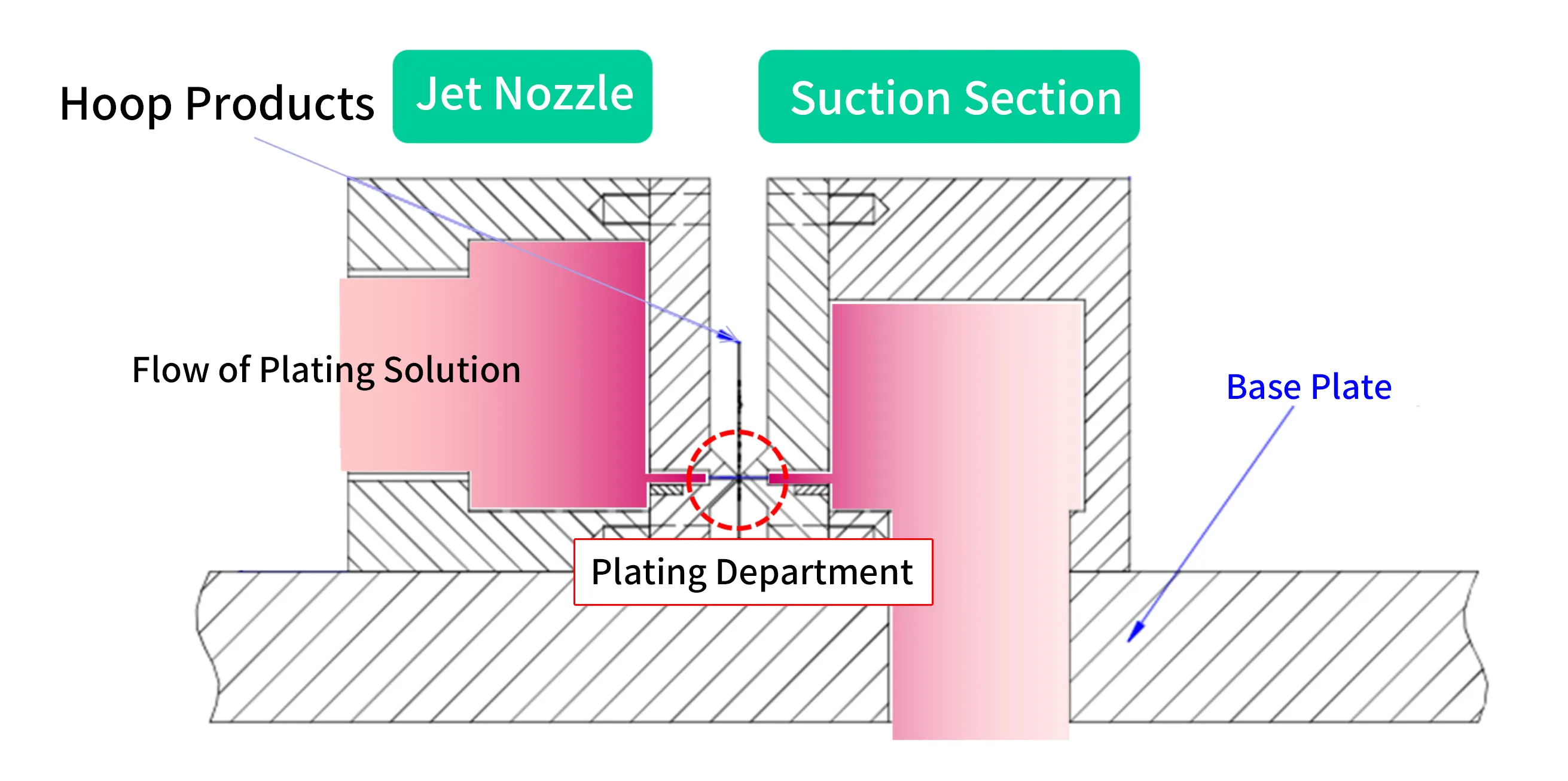

Method-4 : Special Suction Method(Patent No. 5884142)

- Resolved Issues

- The use of expensive specialized plating solutions and laser stripping equipment is mainstream.

- Countermeasure Technology

- Development of a special suction method

- Merits

- Significant cost reduction through high-precision continuous partial plating

Device overview(Patent No. 5884142)

【Features】Rather than the typical “spraying only” structure, it features a “spraying” + “suction” structure.