Stable production through safety and quality

At our company, we aim for thorough quality control. In addition to installing clean rooms, we stabilize the quality of our products by inspecting them at multiple stages using a wide range of inspection equipment.

In order to respond to increasingly sophisticated demands and diversifying evaluation items, we constantly review the effectiveness of our inspection equipment and actively seek to introduce new equipment.

All employees thoroughly understand that a high-quality, stable production system is essential for earning the trust of our customers.

History management using monitoring devices

Our in-house equipment is equipped with units that monitor process conditions such as processing temperature, voltage, and operating speed. These units continuously monitor process conditions and sample and record data at specified intervals.When an abnormality occurs, the alarm sounds and the details of the malfunction, its value, and the date and time of occurrence are recorded.These sampling data and anomaly histories are transferred wirelessly from the monitoring device to the internal data server and stored there.

Comprehensive development support system with a wide range of inspection and testing equipment

In order to respond to increasingly complex and diverse customer needs, such as the refinement of parts, new materials, and environmental considerations, and to develop products that are always ahead of their time, we have established a “Technology Development Center” at our main factory.

As this is a floor dedicated to technological development, prototyping and experimentation can be carried out on a larger scale and more efficiently.In addition, various analytical devices have been prepared, enabling rapid verification of prototype and experimental results and feedback.In addition, the center also has a plating equipment design and manufacturing department, enabling it to provide development support such as modifying experimental equipment as needed.

-

nano-processing microscope(FIB)

SIInano-processing microscope SMI500- Uses and functions

- Micro sectioning and observation

-

Benchtop Scanning Electron Microscope

Made in Japan JCM-7000- Uses and functions

- Surface observation, surface analysis

-

3D shape measuring machine

Manufactured by Keyence VR-5100- Uses and functions

- Surface shape measurement, Roughness measurement

-

digital microscope

Manufactured by Keyence VHX-5000- Uses and functions

- surface observation

-

laser microscope

Manufactured by OLYMPUS OLS-5100- Uses and functions

- Surface observation, roughness measurement, cross-sectional shape measurement, etc.

-

Pressure cooker testing machine

Manufactured by ESPEC EHS-411M- Uses and functions

- Pre-treatment for solder wettability evaluation

-

Meniscograph Manufactured by TARUTIN

SWET-2100- Uses and functions

- Solder wettability evaluation

-

Mixed gas corrosion tester

Yamazaki Seiki Manufacturing Co., Ltd.GH-180- Uses and functions

- corrosion resistance evaluation

-

ESPEC constant temperature and humidity test chamber

Manufactured by ESPEC SH-221- Uses and functions

- corrosion resistance evaluation

-

fluorescent X-ray film thickness gauge

Manufactured by Hitachi High-Tech Science Corporation

FT-160, etc. 8 units in total- Uses and functions

- Plating thickness measurement

-

atomic absorption spectrophotometer

Shimadzu AA-7800- Uses and functions

- Quantitative determination of metal concentration in plating solution, etc.

-

UV-visible spectrophotometer

Shimadzu UV-1800- Uses and functions

- Quantitative determination of the concentration of additives such as plating solutions

-

ICP emission spectrometer

Manufactured by SPECTRO

SPECTROBLUE FMS36- Uses and functions

- Quantitative determination of metal concentration in plating solutions, etc.

-

micro-color difference meter

Manufactured by Nippon Denshoku Kogyo Co., Ltd.

VSR-400 2 units in total- Uses and functions

- Measurement of gloss on plated surfaces

-

salt spray tester

Suga Testing Machine Manufacturing Co., Ltd. STP-90V-4- Uses and functions

- corrosion resistance evaluation

-

Vickers hardness tester

Manufactured by Mitutoyo HM-200- Uses and functions

- hardness evaluation

-

rotary microtome

Manufactured by Leica RM2255- Uses and functions

- Cross-section cutting, thin section preparation

-

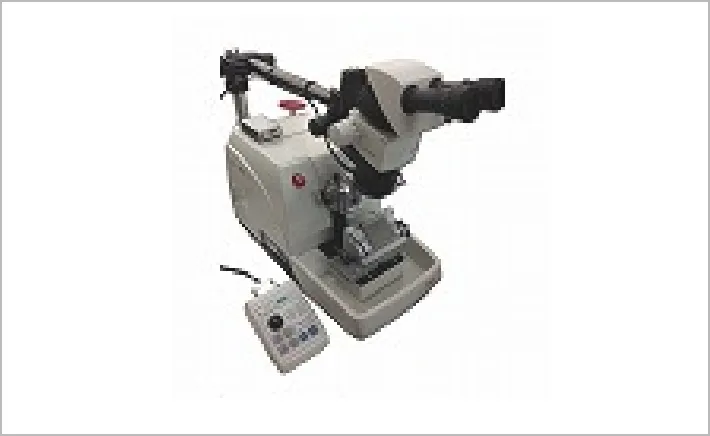

Manual wedge bonder

Manufactured by WEST BOND

MODEL-7476D- Uses and functions

- Bonding test using Au wire and Al wire

-

Bond tester manufactured by Nordson DAGE

4000 Optima- Uses and functions

- Wire bonding and die bonding share strength and pull strength measurement

-

laser marker

Manufactured by Keyence MD-U1000- Uses and functions

- surface treatment