High-Roughness plating

Characteristics of rough plating

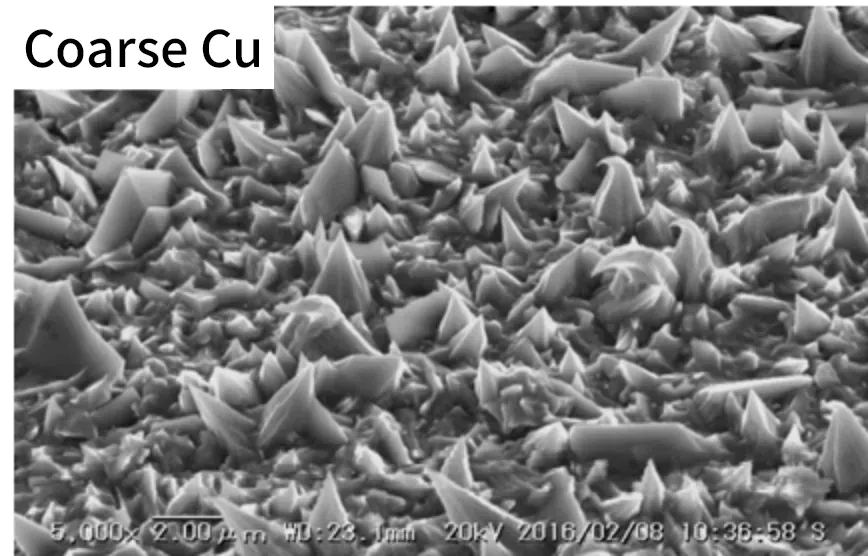

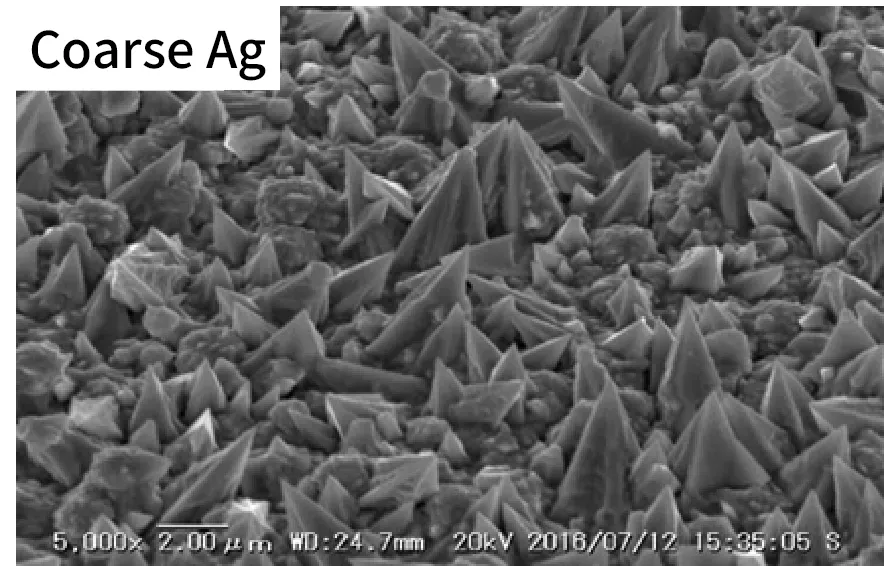

The surface area is increased by a surface shape similar to that of a sword mountain, which is expected to improve adhesion to resin, reduce reflectivity, and improve thermal conductivity.

Another feature is that it does not use additives or alloys, so it retains the original characteristics of the base metal, such as diffusion prevention.

Our company handles crude Ni, crude Ag, and crude Cu.

Although there are limitations depending on the shape, it can also handle single-sided roughening and partial roughening.

Examples of applications for rough plating

- Electronic components requiring mold resin adhesion

* It is also used in various other ways.

Possible processing methods

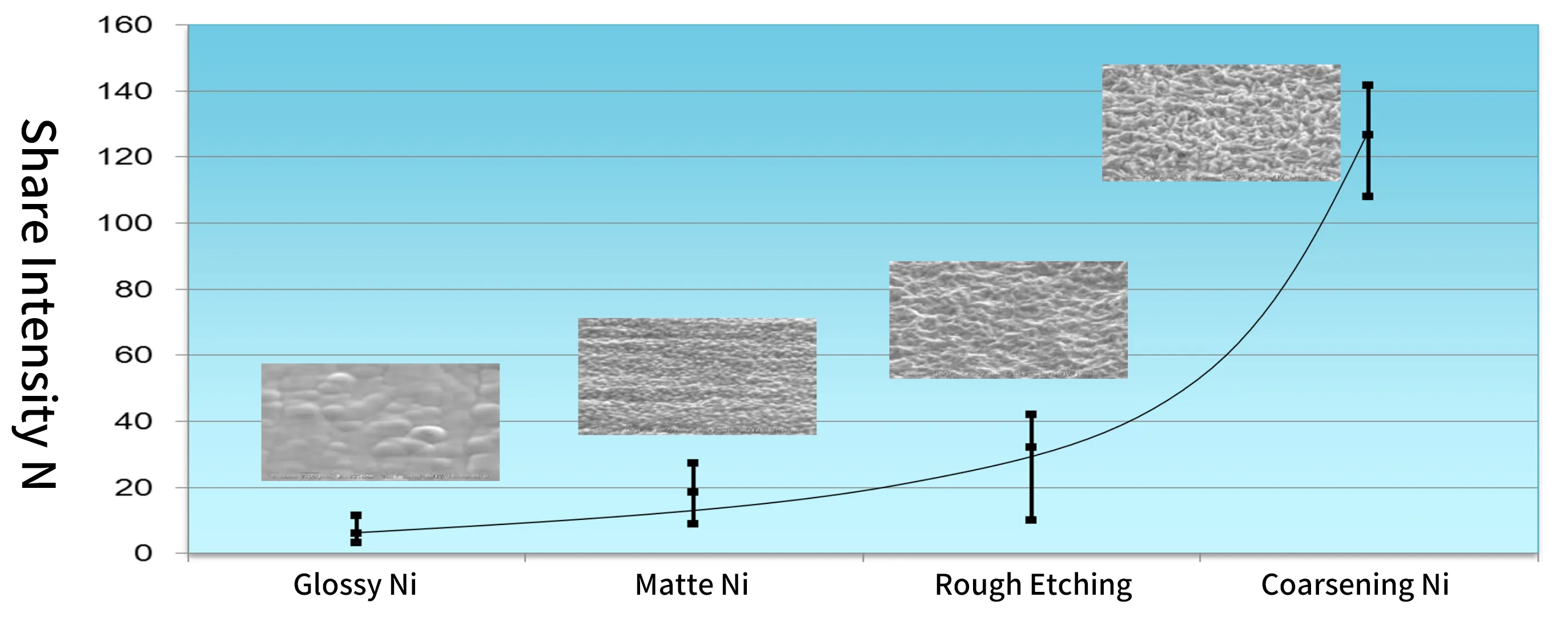

Rough nickel plating

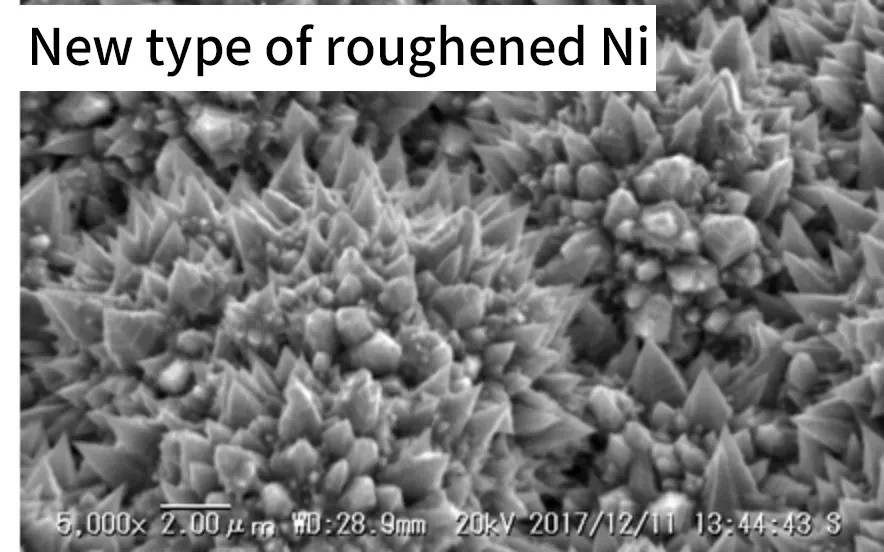

Ueda Plating has developed a nickel plating with a surface texture similar to that of a sword mountain.

Some of them are already in mass production and have a proven track record.

It was developed mainly to improve adhesion to molded resin, but its unique shape is also expected to reduce reflectivity and improve thermal conductivity.

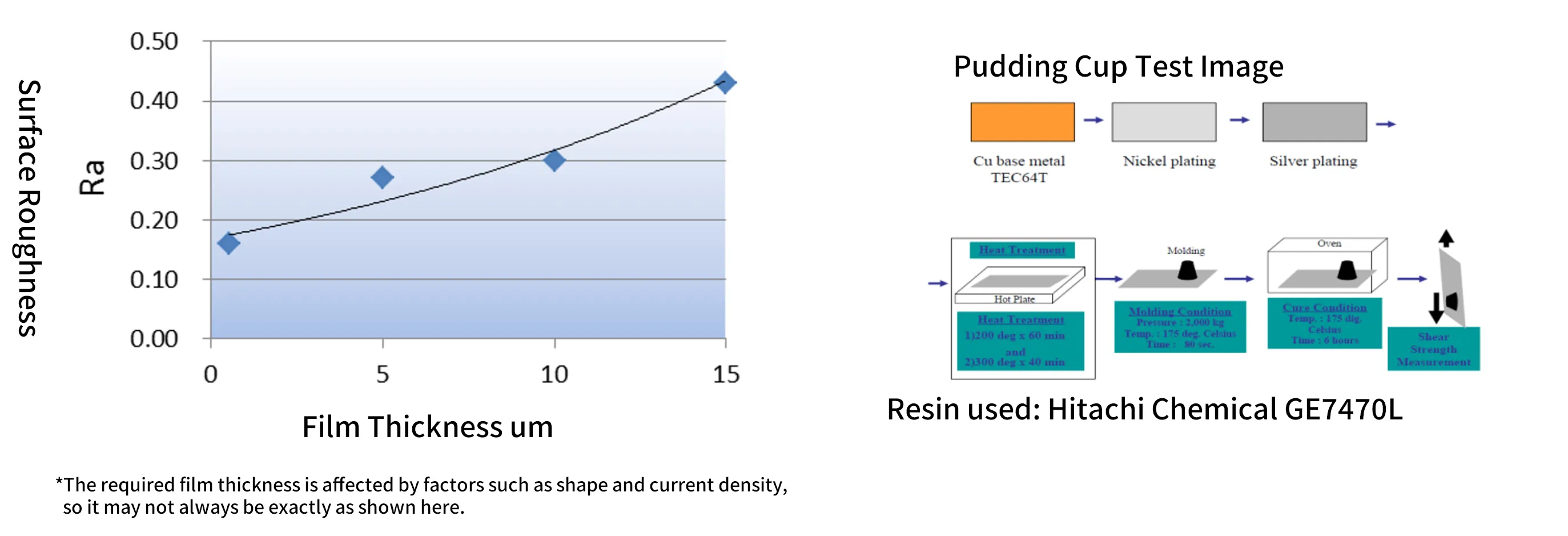

The standard surface roughness is Sa = 0.2 to 0.4 um, Sratio = approx. 1.2, and plating thickness is approx. 2 um.

The surface condition of the material and the type of base plating can also affect the roughness.We will propose the most suitable conditions for your purpose.

Another feature is that it retains the inherent properties of nickel, such as diffusion prevention of the base metal, as it does not contain additives or alloys.

Joint boundary cross section with molded resin

Resin can be seen penetrating the entire roughened surface.

It also supports single-sided roughening and partial roughening.

Rough Plating

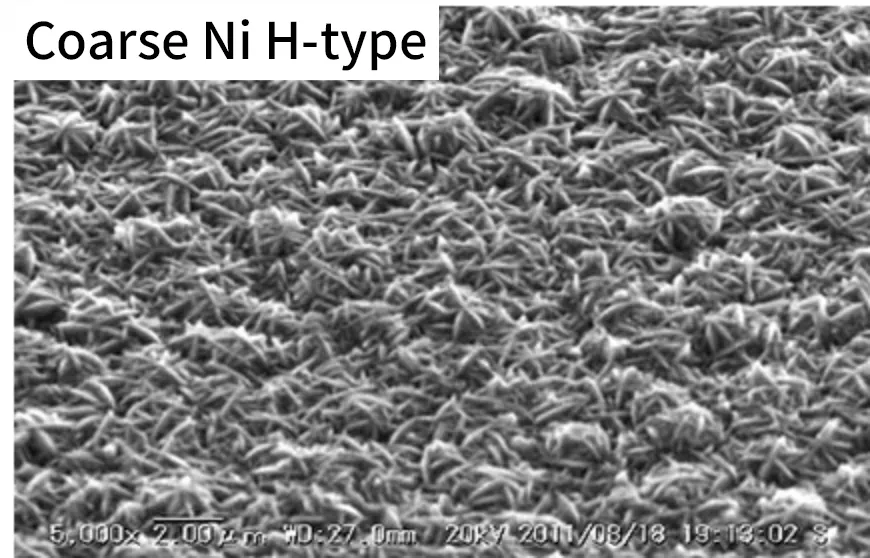

Unlike the smooth surface of non-glossy nickel plating, the surface of roughened nickel plating is roughened with needle-like protrusions, enabling high resin adhesion through the anchor effect.

Since it is not caused by additives or alloying, the inherent properties of nickel, such as diffusion prevention of the base metal, can be maintained.

Variations in rough plating

-

-

-

-

-

-

-

-

-

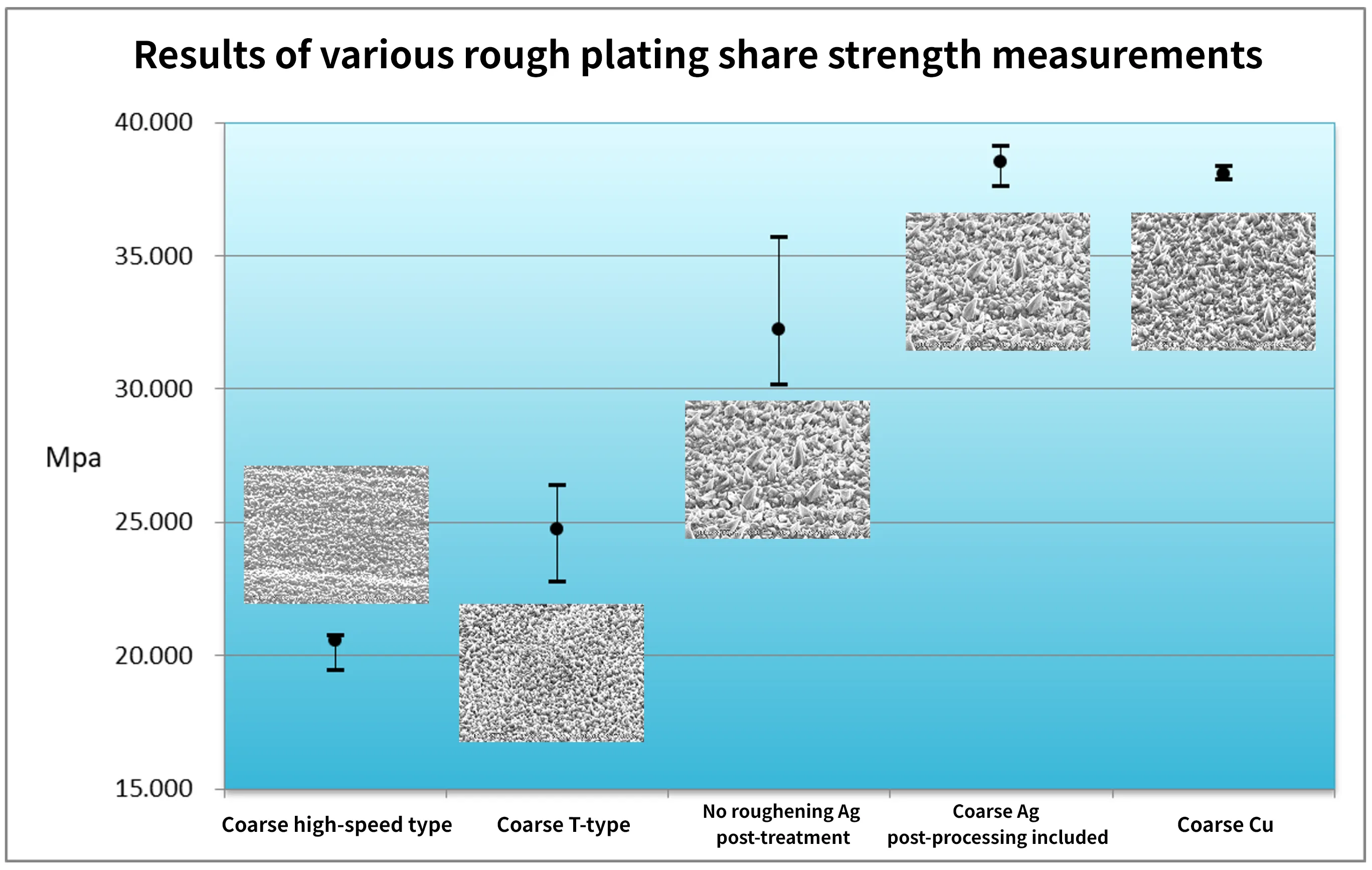

Resin used:Hitachi ChemicalGE7470L

Adhesion strength measurement using a pudding cup mold test

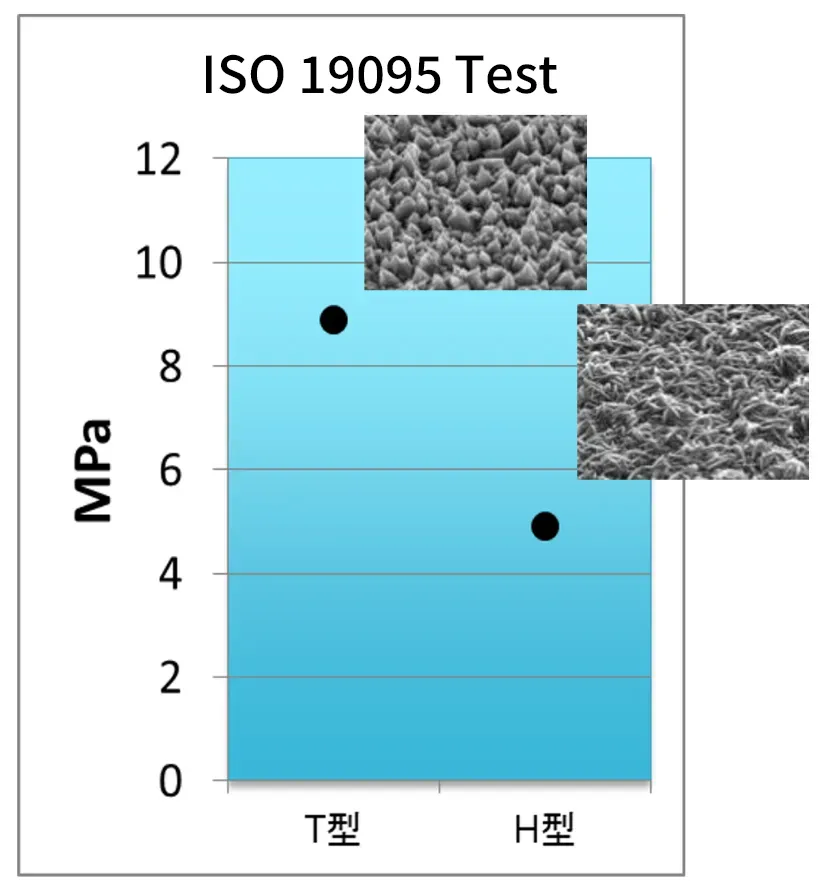

ISO19095 test